|

|

07 October 2010, 23:46

07 October 2010, 23:46

|

#21

|

|

Member

Country: UK - Scotland

Town: Aberdeenshire

Boat name: Sula

Make: Ribcraft 4.8m

Length: 4m +

Engine: Tohatsu 70hp + aux

MMSI: 235087213

Join Date: Jun 2007

Posts: 4,665

|

Update so far. Don't have a multimeter as yet, but have ordered one. Halfords wanted £50, aye that will be right!

Checked the wiring for the PTT motor and there was a little damage to it where part of the rubber sheath was missing. This had been concealed with insulation tape and as a result, the wire was corroded. Thought I'd traced the fault and was as pleased as punch, however connected it to the battery after cutting the wire back, still no joy. I'll replace this entire two-ply wire once I've fixed the fault. Prior to this I'd checked there was power to the PTT with a voltage screwdriver.

I spoke to the Tohatsu service agent who sold me the outboard (it's outside warranty), otherwise it would have been back to him toot-sweet! The engine was on it's side for a couple of months prior to me building the stand for it. All in all it's been laid-up for 10 months. He suggested it's unlikely that the motor is faulty given it's been stored, however the brushes on the motor itself may not be making contact.

When the engine was first connected it dropped an inch or so when the PTT was used, so there was a live feed to it. Only trouble is the leg is in the down position and the only way to access the motor is to remove one side of the outboard clamp. This will mean trying to get hold of a mobile hoist and use the lifting eye on the engine, or alternatively, put it on its side again (my preferred option.)

The motor brushes do sound plausible. I'll replace them as a matter of course, assuming the part can be sourced. I should get a diagram from the service agent to help with this.

I thought it may be possible to manually release the hydraulic ram, and lift the leg. Would this not be a better way to access the motor? I did read in the online Tohatsu manual, that doing this could introduce air into the system, that may take some time to purge.

Any views on this would be welcome. Before doing this I will check the battery and relays with the multimeter to check supply voltage, in case I'm on a wild-goose chase.

__________________

|

|

|

07 October 2010, 23:52

07 October 2010, 23:52

|

#22

|

|

Member

Country: UK - Wales

Town: West Wales

Make: Vipermax 5.8, SR4.7

Length: 5m +

Engine: 150 Opti, F50EFi

Join Date: Sep 2005

Posts: 6,299

|

I know I go on about this, but have you checked whether the Red cable from both PTT relays is connected to the heavy Red cable from the battey, on the starter solenoid terminal?

__________________

|

|

|

08 October 2010, 08:48

08 October 2010, 08:48

|

#23

|

|

Member

Country: UK - Scotland

Town: Aberdeenshire

Boat name: Sula

Make: Ribcraft 4.8m

Length: 4m +

Engine: Tohatsu 70hp + aux

MMSI: 235087213

Join Date: Jun 2007

Posts: 4,665

|

Quote:

Originally Posted by Downhilldai

I know I go on about this, but have you checked whether the Red cable from both PTT relays is connected to the heavy Red cable from the battey, on the starter solenoid terminal?

|

Yes, there's a smaller red cable from the (+) battery cable on the starter solenoid to both relays. I also by-passed the relays and connected the PTT cable straight to the battery. No response. Before I proceed with anything - I will double-check readings from the multimeter when it arrives. Cheers for help!

__________________

|

|

|

08 October 2010, 10:41

08 October 2010, 10:41

|

#24

|

|

Member

Country: UK - Wales

Town: West Wales

Make: Vipermax 5.8, SR4.7

Length: 5m +

Engine: 150 Opti, F50EFi

Join Date: Sep 2005

Posts: 6,299

|

Ok, sounds like a problem with the PTT pump motor. I would firstly try releasing the valve on the PTT system and tilting the outboard manually, then try it again on the motor.

__________________

|

|

|

09 October 2010, 23:39

09 October 2010, 23:39

|

#25

|

|

Member

Country: UK - Scotland

Town: Aberdeenshire

Boat name: Sula

Make: Ribcraft 4.8m

Length: 4m +

Engine: Tohatsu 70hp + aux

MMSI: 235087213

Join Date: Jun 2007

Posts: 4,665

|

Quote:

Originally Posted by Downhilldai

Ok, sounds like a problem with the PTT pump motor. I would firstly try releasing the valve on the PTT system and tilting the outboard manually, then try it again on the motor.

|

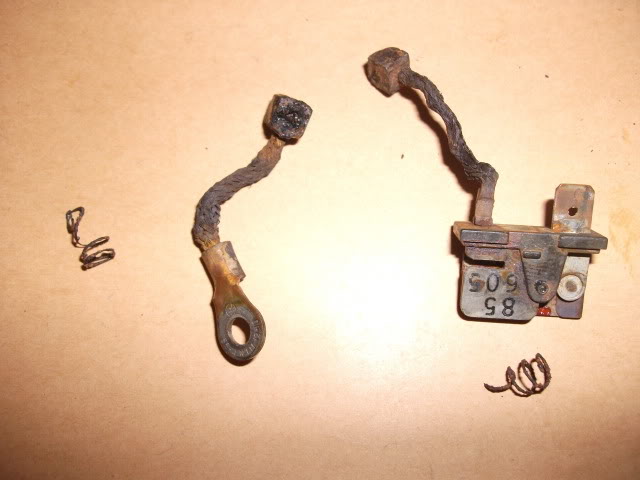

Found the problem. Stripped the starter motor - see pictures. For those of you who have a dodgy starter motor on a Twatsoo, then this is what you need to do.

Starter motor is on the trim and tilt, held in place with (4x) 10mm hex bolts. There is a cross-head on them, but don't cut corners, use the socket. Opened the manual release on the hydraulic ram (4 turns anti-clockwise) and lifted the leg, support on a wooden support. The trim sensor and and PTT power cable need to be removed so you can access the bolt head. You can access the motor by taking the outboard clamp off one side (more trouble than it's worth), as you'll need to lift the engine on a mobile hoist. I opted to access it under the leg. (3x) 10mm bolts are straight forward. The fourth bolt is hidden at the back on the left hand side. It's only accessible using a 1/4" socket with a couple of small 50mm extension lengths and a multi-directional head. Managed to get it out, using a torch and nimble fingers.

You'll lose a little PTT fluid, but there's no choice. You can undo the PTT fluid reservoir cap to release any remaining pressure.

With the starter motor removed, take care not to damage the rubber 'o' rings. There's two to remove. If they look worn, then replace. Remember to use a little ATF fluid to lubricate when refitting.

The power-trim motor is original, so needed a little gentle persuasion to separate. Use a rubber mallet on a block of wood and rotate the motor, and bang at regular intervals. It will eventually ease and release.

Inside, I found that the motor had probably done more hours than I'd been lead to believe. The magnets were worn right down and the springs were non-existant. The copper coiled spindle was in remarkably good condition. Cleaned it up, used a copper wire brush to clean any excess surface corrosion and cleaned the housing. Used a little bearing grease for the top of the spindle where it sits in the metal housing.

The magnets or brushes were goosed. Quick call to a Twatsoo dealer. Turns out this is not available as a separate item only a complete part only at £120.00. Words defy me. Surely in this day and age, in our deposable world, a couple of magnetic brushes (probably retail for under £5.00) can be sourced? I refuse to pay top-dollar for a component that can be fixed. I'll call local motor factors on monday to dee if I can source similar components.

Fitting in reverse. Once it's all connected, manually lift and lower and the leg three to four times. Now close the hydraulic valve and use the PTT. When its in raised position check fluid level. Top up as required. Uses ATF fluid (red in colour) to meet specification. You may need to do this a few times to purge any air in the system. The ATF fluid as shipped from the factory is Nisseki ATF Dextron fluid, (GM approved). It says in the manual if you're mixing fluids, then drain and refill...

Thank you to everyone that's contributed and offered help.

Pictures of the PTT motor as it came off the engine.

__________________

|

|

|

10 October 2010, 08:20

10 October 2010, 08:20

|

#26

|

|

RIBnet admin team

Country: UK - Scotland

Boat name: imposter

Make: FunYak

Length: 3m +

Engine: Tohatsu 30HP

MMSI: 235089819

Join Date: Sep 2005

Posts: 11,639

|

Quote:

|

The magnets were worn right down and the springs were non-existant.

|

I may be wrong, or misunderstanding which part of your motor is worn, but I don't think the brushes are magnetic. They are normally (AFAIK) shaped pieces of carbon (graphite) and provide the electrical contact to the motor. I think that is what is in your picture, and what will have worn.

I'd hope you can either get replacement brushes somewhere (easier if you can identify who actually makes the motor?) or possibly send it to someone to be reconditioned? for less than £120 for a new motor. However there may be some reasons why Tohatsu don't consider it worth offering brushes separately? e.g. if the average life of brushes is X hrs and the average life of the motor is less than 2X hrs then there may be no point in replacing brushes on an old motor. Alternatively it may simply be a commercial decision (especially if they buy motor assemblies complete) - cost of stocking/storing/shipping a £5 part far outweighs the profit they can make on it. If a Tohatsu dealer is fitting you've probably got the choice of a £300 repair (including whole new motor) or £200+ repair (just doing the brushes).

__________________

|

|

|

10 October 2010, 18:34

10 October 2010, 18:34

|

#27

|

|

Member

Country: UK - Scotland

Town: Aberdeenshire

Boat name: Sula

Make: Ribcraft 4.8m

Length: 4m +

Engine: Tohatsu 70hp + aux

MMSI: 235087213

Join Date: Jun 2007

Posts: 4,665

|

Quote:

Originally Posted by Polwart

I may be wrong, or misunderstanding which part of your motor is worn, but I don't think the brushes are magnetic.

|

You're quite right Polwart. I thought they were magnetic, but are as suggested carbon brushes. I've had a quick look online and reckon I can do something Heath-Robinson with Ducatti brushes. I'll source springs elsewhere. No idea who makes the motor, there's no manufacturer stamp, however the cable says 'Tonichik Yosan 2005' Sounds Japanese to me. Quick google search pulls this up. Now renamed Hitachi. They might only make the cable, but I'm sure they're involved in starter motors too. http://www.hitachi-cable.co.jp/en/ab...ory/index.html

Quote:

|

If a Tohatsu dealer is fitting you've probably got the choice of a £300 repair (including whole new motor) or £200+ repair (just doing the brushes).

|

Genuine Tohatsu replacement part is £120. Wouldn't take longer than an hour to fit. I'll fit new brushes myself (£10 delivered) and test. Add £10 for replacement ATF Dextron fluid to top up. £20 repair if it goes according to plan.

Multi-meter arrived yesterday. Battery had been on a trickle charge (topped up with distilled water). Left it all day today without the charger and it measured a healthy 13.4v.

__________________

|

|

|

13 October 2010, 22:41

13 October 2010, 22:41

|

#28

|

|

Member

Country: UK - Scotland

Town: Aberdeenshire

Boat name: Sula

Make: Ribcraft 4.8m

Length: 4m +

Engine: Tohatsu 70hp + aux

MMSI: 235087213

Join Date: Jun 2007

Posts: 4,665

|

Story so far.

Completely stripped the trim motor. Apart from a little surface corrosion, the armature was in excellent condition. Cleaned both parts of the casing, and lightly sanded the channels where the brushes sit. On the topic of the brushes, they're no longer available as a Tohatsu part. Searched online and found these (for a Honda CBR 125). The bolt and small eye contact were simply clipped off. The copper weave attachment on the brushes were fused with the existing weave using a metal clip (and plastic sleeve to insulate it). The brushes almost fitted like a glove, but were slightly too deep. Quick sand with an emery board and I reduced them to the required height. A very fine smear of Castrol marine grease was used in the housing channels and on the bearing ends. In addition, I'd sourced some 5mm springs. These provide tension on the brushes and force them to make contact with the armature contacts. Add the 'o' ring (lubricate with a little ATF fluid) and close the trim motor. Quick test and it fired into life.

Although I'm happy that I've put this back together and it works, it's not 100%, and I suppose I'll always have a nagging feeling that it will let me down when I least expect it. I can always keep it as a spare. Calling Tohatsu tomorrow to order the replacement part.

Cheers for all your help. At least I know how the bleed'n trim motor works now.

__________________

|

|

|

30 October 2010, 22:18

30 October 2010, 22:18

|

#29

|

|

Member

Country: UK - Scotland

Town: Aberdeenshire

Boat name: Sula

Make: Ribcraft 4.8m

Length: 4m +

Engine: Tohatsu 70hp + aux

MMSI: 235087213

Join Date: Jun 2007

Posts: 4,665

|

Change of plan. Fitted the repaired unit today as I feel confident in the repair and it works like a dream. Ordered replacement springs from Meccano! The original springs I used were far too stiff, so I replaced them with compression springs for Meccano for £1.99. (Part is 120b). Fits like a glove, plenty compression and a little Castrol marine grease to keep corrosion at bay.

With everything back together, I had the arduous job of bleeding the system. For those of you that hate to bleed brakes on a car, then this comes a close second.

Used Mobil ATF220 fluid to top up reservoir. With the manual hydraulic release in the open position, I had to lift and lower the leg 5 times. The leg needs to be lowered before opening the valve. Topped up reservoir to lower level, and repeated the whole process probably 3-4 times. Sure I've lifted that bleed'n leg 20 times! Close valve and use power-trim. Now lifts without hesitation.

__________________

|

|

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

Recent Discussions

Recent Discussions |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|