|

|

15 September 2012, 09:04

15 September 2012, 09:04

|

#101

|

|

Member

Country: France

Town: Huisnes sur Mer

Boat name: Raufoss

Make: Avon

Length: 4m +

Engine: Mercury 50

Join Date: Sep 2010

Posts: 789

|

Quote:

Originally Posted by BogMonster

^

I think you'll get a vibration problem with those triangular wheels

|

Stephen, got your PM and am starting to agree with you....

" A little bit of knowledge is a dangerous thing "

Quote:

Originally Posted by Boats&Outboards

Simon - At last. Why didn't you just admit you were wrong in the first place :ROFL:

Peter @ Boatsandoutboards4sale ~ askboatsandoutboards4sale@sky.com ~ 07930 421007 |

Peter, why didnt you tell me sooner? i could have gone and done much more productive things with my time like count how many shitehawks have flown past the oil terminal in the last few days

Simon

__________________

C'est pas l'homme qui prend la mer, c'est la mer qui prend l'homme....

|

|

|

15 September 2012, 09:06

15 September 2012, 09:06

|

#102

|

|

Member

Country: UK - England

Town: Zummerset

Boat name: irven arlyss

Make: Humber Oceanpro

Length: 6m +

Engine: evinrude 135hp

Join Date: May 2012

Posts: 394

|

Quote:

Originally Posted by Anchorhandler

To give you a bit of background, i'm a mechanical engineer. I run a small engineering workshop in my spare time and when im not doing that i subcontract full time for a multi-national oil company..... Wait for it.... As a chief engineer.

Oh and i also have an HGV2 ticket and run a DAF LF55 crane lorry as part of the workshop.

|

Obviously Jeepster knows more, and is much more qualified!

I say you should encourage him to remove at least 90% of the material, as he thinks this will make it stronger, and it might never leave his driveway then!, safest thing all round!

Just as an afterthought does this chap not sound very similar in his posts to a recent poster?? "SR4" maybe he has been reincarnated.......

__________________

|

|

|

15 September 2012, 09:08

15 September 2012, 09:08

|

#103

|

|

Member

Country: UK - England

Length: 3m +

Join Date: Sep 2008

Posts: 2,767

|

If you want to save weight on the trailer just drop the lengthwise bars alltogether. Balance the boat very carefully on the axle and pull it by the painter. I'm not a structural engineer or anything but I'm sure you'll have reduced the trailer weight by the maximum amount possible and it'll stop these guys all shouting at you about the dimensions of the box section.

Just think of it as drilling a really big lightening hole!

Now if you had a RIB you could also fill the tubes with hellium (if these guys suggest hydrogen they are just taking the weight reduction too far). Hellium is lighter than air so you'd have less weight to move around. Maybe you have bouyancy tanks and can achieve the same thing??

__________________

|

|

|

15 September 2012, 09:23

15 September 2012, 09:23

|

#104

|

|

Member

Country: France

Town: Huisnes sur Mer

Boat name: Raufoss

Make: Avon

Length: 4m +

Engine: Mercury 50

Join Date: Sep 2010

Posts: 789

|

Quote:

Originally Posted by Leapy

It did at first but then it dropped out. Must have been overloaded  |

Leapy...got your PM..thanks...

Tonto...dont you start n'all....

Now back to counting shitehawks....

Simon

__________________

C'est pas l'homme qui prend la mer, c'est la mer qui prend l'homme....

|

|

|

15 September 2012, 09:33

15 September 2012, 09:33

|

#105

|

|

Member

Country: UK - England

Length: 3m +

Join Date: Sep 2008

Posts: 2,767

|

Quote:

Originally Posted by tonto

"SR4" maybe he has been reincarnated.......  |

Really? He's not mentioned painting the trailer orange... ...yet!

__________________

|

|

|

15 September 2012, 09:35

15 September 2012, 09:35

|

#106

|

|

Member

Country: UK - England

Town: Up Norf

Make: Avon SR4,Tremlett 23

Length: 4m +

Engine: Yam 55, Volvo 200

Join Date: Apr 2007

Posts: 5,217

|

Quote:

Originally Posted by ShinyShoe

Really? He's not mentioned painting the trailer orange... ...yet!

|

Painting certain bits of the trailer will make it stronger too, obviously if you painted all of it it would weaken it!

__________________

|

|

|

15 September 2012, 09:49

15 September 2012, 09:49

|

#107

|

|

Member

Country: France

Town: Huisnes sur Mer

Boat name: Raufoss

Make: Avon

Length: 4m +

Engine: Mercury 50

Join Date: Sep 2010

Posts: 789

|

Quote:

Originally Posted by ShinyShoe

If you want to save weight on the trailer just drop the lengthwise bars alltogether. Balance the boat very carefully on the axle and pull it by the painter. I'm not a structural engineer or anything but I'm sure you'll have reduced the trailer weight by the maximum amount possible and it'll stop these guys all shouting at you about the dimensions of the box section.

Just think of it as drilling a really big lightening hole!

|

Best reply to this thread yet....

Oh, there goes another shitehawk too.....

Simon

__________________

C'est pas l'homme qui prend la mer, c'est la mer qui prend l'homme....

|

|

|

15 September 2012, 10:08

15 September 2012, 10:08

|

#108

|

|

RIBnet admin team

Country: UK - Scotland

Boat name: imposter

Make: FunYak

Length: 3m +

Engine: Tohatsu 30HP

MMSI: 235089819

Join Date: Sep 2005

Posts: 11,636

|

Quote:

Originally Posted by ShinyShoe

Really? He's not mentioned painting the trailer orange... ...yet!

|

As he's not galvanised it, it will turn 'orange' all by itself in time.

__________________

|

|

|

15 September 2012, 10:11

15 September 2012, 10:11

|

#109

|

|

Member

Country: France

Town: Huisnes sur Mer

Boat name: Raufoss

Make: Avon

Length: 4m +

Engine: Mercury 50

Join Date: Sep 2010

Posts: 789

|

Quote:

|

Originally Posted by Poly

As he's not galvanised it, it will turn 'orange' all by itself in time.

|

And he wont then need to drill those infamous holes in it.... :-)

Simon

Sent from my iPhone using Rib.net

__________________

C'est pas l'homme qui prend la mer, c'est la mer qui prend l'homme....

|

|

|

15 September 2012, 10:26

15 September 2012, 10:26

|

#110

|

|

RIBnet admin team

Country: UK - England

Town: The wilds of Wiltshire

Boat name: Dominator

Make: SR5.4

Length: 7m +

Engine: Yam 85

MMSI: 235055163

Join Date: Jul 2005

Posts: 13,069

|

I think he should cut some lightening holes in the boat.

__________________

Need spares,consoles,consumables,hire,training or even a new boat?

Please click HERE and HERE and support our Trade Members.

Join up as a Trade member or Supporter HERE

|

|

|

15 September 2012, 11:26

15 September 2012, 11:26

|

#111

|

|

Member

Country: UK - England

Town: London

Boat name: Jeepster

Make: Marina 16 GT

Length: 5m +

Engine: Outboard, Petrol, 30

Join Date: Sep 2012

Posts: 52

|

Quote:

Originally Posted by Anchorhandler

Jeepster.....

I have remained quite polite throughout this thread but you really are testing my patience now ...

Uf your going to try and use something like Mitcalc the at least try to learn fundamental mechanics beforehand.

|

Are you sure you know how to use MITcalc? Your model would imply that you don't.

Quote:

Originally Posted by Anchorhandler

In simple terms, the weight of your trailer is being transferred down to the axle through 4 seperate points, the connection points where the swing beams meet the rails.... Follow me so far?

|

Are you just being dense on pupose? If you look at my MITcalc model it clearly shows the exact positions of the "4 connection points", relative to the axle ie: The swingbeam pivots, where the the force is being applied to the siderails.

Being two dimensional, of course it only shows a single beam, but this beam is of course made of two seperate 80x40x3 RHS rails, so you can double the strength of the beam...Or perhaps you failed to realise that?

Quote:

Originally Posted by Anchorhandler

This force then gets added to the downward force that the weight of the trailer is also generating on the axle.

|

Just as my model takes into account!

Quote:

Originally Posted by Anchorhandler

Now for the important bit..... Listen carefully

FORGET YOUR FECKING TOWHITCH!!!!!!

|

Its not going to happen...Its part of my model so it stays.

Quote:

Originally Posted by Anchorhandler

I have worked out the stress on the longitudinal rails as this is quite obviously the most heavily loaded part if your trailer.

|

So have I, but your model looks nothing like mine and therefore you have different results.

And just FYI, after the axle, the rear swingbeam is the most heavily loaded part of my trailer, not the siderails!

Quote:

Originally Posted by Anchorhandler

Your just going to have to take my word for it as its quite clear that your unable to grasp this but the the weight of the boat is trying to bend the side rails over the top of axle.

|

And which part of my model, that clearly shows exactly that, didn't you understand?

Quote:

Originally Posted by Anchorhandler

As your now infamous towhitch can only take 50kgs so its hardly worth subtracting this from the downward thrust created by the forward swingbeam. ( plus i would have to calculate the moment based on the distance to the forward swingbeam itself anyway)

|

That 50kg is part of the equation, so I am not simply going to ignore it.

Quote:

Originally Posted by Anchorhandler

Now look carefully at what you tried to simulate on Mitcalc....

WHY HAVE YOU SIMULATED AN UPWARDS THRUST RIGHT AT THE END OF THE TRAILER?

|

...Its called the towhitch!

Quote:

Originally Posted by Anchorhandler

How many fecking axles does your trailer have?

|

...I told you it only has one axle, my photos clearly show it only has one axle and my MITcalc model only has one axle...Which part of "one axle" don't you understand???

Quote:

Originally Posted by Anchorhandler

Also you need to learn a bit more about steel grades also.

|

I have included the steel grade in my model, have you?

Quote:

Originally Posted by Anchorhandler

If your going to jump in at the deep end, FFS learn how to swim first!!

|

I am wearing my life jacket, so I am not too worried.

Quote:

Originally Posted by Anchorhandler

To give you a bit of background, i'm a mechanical engineer. I run a small engineering workshop in my spare time and when im not doing that i subcontract full time for a multi-national oil company..... Wait for it.... As a chief engineer.

|

With that in mind, I'm glad I am not one of your clients!

Quote:

Originally Posted by Anchorhandler

Oh and i also have an HGV2 ticket and run a DAF LF55 crane lorry as part of the workshop.

The picture of the trailer i built i posted earlier is ( i think) the 6th trailer i have built to date. (four of which were braked trailer with at least a 2000kg gross weight)

Now if you still don't trust what im saying ithen fair enough but i have shown you 4 other examples of other trailer manufacturers pridung a 1300kg trailer and each shows a reinforced side rail. .

|

...Please read my previous posts before you reach for your keyboard...In one of my recent posts I clearly state that mine is actually based on a 1100kg Indespenion trailer, and they do not have reinforced side rails!

I even showed a photo of the trailer in question.

Quote:

Originally Posted by Anchorhandler

Why am i wasting my time here?

|

Amen!

Quote:

Originally Posted by Anchorhandler

You know what,,,, go ahead, your trailer IS perfectly safe in fact your right about drilling holes down the side of the rails and your right also about loading up the towhitch too.

Good luck to you (and to the other road users who are following you down the road.

Simon

Sent from my iPhone using Rib.net

|

They had better not get behind an 1100kg gross Indespension trailer either, because according to you they aren't structurally sound!

__________________

|

|

|

15 September 2012, 12:05

15 September 2012, 12:05

|

#112

|

|

RIBnet admin team

Country: UK - Scotland

Boat name: imposter

Make: FunYak

Length: 3m +

Engine: Tohatsu 30HP

MMSI: 235089819

Join Date: Sep 2005

Posts: 11,636

|

Out of interest when trailers fail (from being overloaded) is it the vertical force that actually kills them or perhaps the roll/yaw/cornering force? It strikes me that a trailer could survive being overloaded sitting in the yard but the dynamic load going over a speed bump or the g force going round a corner will be much higher and less predictable. Of course if it fails in the yard its possibly expensive and inconvenient. If it fails at 40mph on a corner its possibly manslaughter.,

__________________

|

|

|

15 September 2012, 12:10

15 September 2012, 12:10

|

#113

|

|

Member

Country: UK - England

Town: Zummerset

Boat name: irven arlyss

Make: Humber Oceanpro

Length: 6m +

Engine: evinrude 135hp

Join Date: May 2012

Posts: 394

|

Quote:

Originally Posted by Poly

Out of interest when trailers fail (from being overloaded) is it the vertical force that actually kills them or perhaps the roll/yaw/cornering force? It strikes me that a trailer could survive being overloaded sitting in the yard but the dynamic load going over a speed bump or the g force going round a corner will be much higher and less predictable. Of course if it fails in the yard its possibly expensive and inconvenient. If it fails at 40mph on a corner its possibly manslaughter.,

|

Particularly if you are daft enough to build it without knowing what you are doing!

Ignorance is no defense under the law. Much better to leave these things to people who know what they are doing, and carry public liability insurance, and prepared to give it a certificate.

I would suggest that after jeepster finishes cutting all his holes he takes it along to a VOSA center and see what they think of it. (without his boat on I would suggest!)

__________________

|

|

|

15 September 2012, 12:15

15 September 2012, 12:15

|

#114

|

|

Member

Country: UK - England

Town: London

Boat name: Jeepster

Make: Marina 16 GT

Length: 5m +

Engine: Outboard, Petrol, 30

Join Date: Sep 2012

Posts: 52

|

Quote:

Originally Posted by tonto

Particularly if you are daft enough to build it without knowing what you are doing!

Ignorance is no defense under the law. Much better to leave these things to people who know what they are doing, and carry public liability insurance, and prepared to give it a certificate.

I would suggest that after jeepster finishes cutting all his holes he takes it along to a VOSA center and see what they think of it. (without his boat on I would suggest!)  |

I didn't say I was going to cut holes in my trailer, it was just a suggestion. You have got the hole thing mixed up!

__________________

|

|

|

15 September 2012, 12:20

15 September 2012, 12:20

|

#115

|

|

Member

Country: UK - England

Town: Littlehampton, W Sx

Length: no boat

MMSI: 235101591

Join Date: Jan 2012

Posts: 732

|

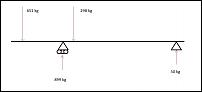

In the spreadsheet Jeepster seems to have point loads and continuous loading muddled up and the beam dimensions (breadth and depth) the wrong way round. How about we ignore the weight of the beams for now (getting rid of the continuous loading)?

If we kept it simple, would Simon and Jeepster agree that the loading might look something like this?

Shear force and bending moment like this?

And work it out from there?

Second moment of area of the beam is (40 x 80^3) / 12 - (36 x 74^3)/12

(My university days were more than half my life behind me now!)

__________________

|

|

|

15 September 2012, 12:54

15 September 2012, 12:54

|

#116

|

|

Member

Country: UK - England

Town: London

Boat name: Jeepster

Make: Marina 16 GT

Length: 5m +

Engine: Outboard, Petrol, 30

Join Date: Sep 2012

Posts: 52

|

Quote:

Originally Posted by Anchorhandler

Yeah....

I wasnt going to reply anymore as its pretty clear there is nothing on this forum that you either dont already know or dont want to hear but since the safety of other road users comes into it i figured i better post these pictures....

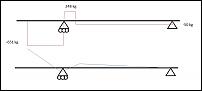

They both show the computer simulation of the loading on each side of the trailer based on forces being applied at the points you have indicated. Picture 2 follows from the bottom of picture 1.

As you can see, the first shows a simple forces diagram showing the current set-up of your trailer....

I have allowed for a 6" landing area where the axle meets the side rails.

I have also set this up on the assumption that you have used a 50B grade steel or similar.

I have simulated a 200kg force forward and a 210kg force aft (at the points that the swingbeams connect to the rails.

This gives you a total loading of (200x2)+(210x2)= 820kgs

If you loook at the second picture you can see that in your case you are on the absolute limit of the permissible stress allowed in the steel. (Highlighted red, 208Mpa out of 207Mpa m, ax). Beyond this you risk deforming the steel leading to possible failure. Incidentally It also shows a maximum deflection of 18mm

Keep in mind that i havnt subjected the loadings to any safety factor either.

Your best option to render this safer is to move the rear swingbeam further forward thus reducing the bending moment on the side rails.

But of course... you already knew all this didnt you?

Simon |

I just had another look at your MITcalc model...Oh dear!

You appear to have the load equally distributed at either end of the beam, and two axles! Plus you only calculated the bending stress for a single 80x40x3 beam, not for two as is the case with my trailer!

And you call yourself a chief engineer?

__________________

|

|

|

15 September 2012, 13:55

15 September 2012, 13:55

|

#117

|

|

RIBnet admin team

Country: UK - England

Town: The wilds of Wiltshire

Boat name: Dominator

Make: SR5.4

Length: 7m +

Engine: Yam 85

MMSI: 235055163

Join Date: Jul 2005

Posts: 13,069

|

Quote:

Originally Posted by jeepster

I just had another look at your MITcalc model...Oh dear!

You appear to have the load equally distributed at either end of the beam, and two axles! Plus you only calculated the bending stress for a single 80x40x3 beam, not for two as is the case with my trailer!

And you call yourself a chief engineer?  |

No, but you are by your own admission an unemployed toy lorry driver...

__________________

Need spares,consoles,consumables,hire,training or even a new boat?

Please click HERE and HERE and support our Trade Members.

Join up as a Trade member or Supporter HERE

|

|

|

15 September 2012, 14:00

15 September 2012, 14:00

|

#118

|

|

Member

Country: France

Town: Huisnes sur Mer

Boat name: Raufoss

Make: Avon

Length: 4m +

Engine: Mercury 50

Join Date: Sep 2010

Posts: 789

|

Quote:

Originally Posted by jeepster

I just had another look at your MITcalc model...Oh dear!

You appear to have the load equally distributed at either end of the beam, and two axles! Plus you only calculated the bending stress for a single 80x40x3 beam, not for two as is the case with my trailer!

And you call yourself a chief engineer?  |

Yes actually, i do call myself a Chief Engineer....

The load is equally distibuted at both ends because, as i mentioned, i'm only intrested in calculating the stress in the side rails at the area they connect with the axle. This is the most critical part of any trailer.

Re-read post number 86 and you will see that i mention a 150mm area where the rails connect to the axle....this is represented in the drawings by the two black triangles....funny enough, spaced 150mm apart.

If you also look at the calculations i have given you in the same post (200 X2)+(210 X2)=820Kgs, i thought it would have been obvious that the calculation was for one rail only considering i'm multiplying the loadings by two to account for the whole trailer.

I gave you an estimated maximum loading for your design of trailer at 820Kgs....based on my calculations. Have you actually checked what an Indespension 1100kg trailer is rated to carry? Funny enough i just have a few minutes ago... 800Kg max!

So not only are my calculations correct, it means that this fantastic trailer you've constructed is very nearly on the absolute limit for what your boat weighs....better not think of uprating that engine for a while then!

I also suggested you move the rear swingbeam forward to make it safer.....Look at the bending diagram and shear force diagram HughH has kindly uploaded and pay rarticular attention to the high bending/Shear force at the rear of your trailer (P.S. Thanks for taking the time to do this Hugh).

Finally, look at the calculations YOU have used and exoplain to me what is wrong here....Where did you get a 440 odd tonne load from? and, as Hugh also questions....where has the uniform loading come from?

Both myself and others on here have genuinly tried to give you sound advise but you have chosen to refute it each and every time....

Before i bid farewell to you one final time......remember this.

"We are all born with two ears, two eyes and one mouth....and we should always try to use them in that proportion"

Good luck to you Jeepster

Simon

__________________

C'est pas l'homme qui prend la mer, c'est la mer qui prend l'homme....

|

|

|

15 September 2012, 14:35

15 September 2012, 14:35

|

#119

|

|

RIBnet admin team

Country: UK - Scotland

Boat name: imposter

Make: FunYak

Length: 3m +

Engine: Tohatsu 30HP

MMSI: 235089819

Join Date: Sep 2005

Posts: 11,636

|

Quote:

Originally Posted by Anchorhandler

"We are all born with two ears, two eyes and one mouth....and we should always try to use them in that proportion"

|

Ah, but the he had ten fingers (although apparently none of them could find the return key in his OPs!). So that lets him type a lot...

__________________

|

|

|

15 September 2012, 15:23

15 September 2012, 15:23

|

#120

|

|

Member

Country: UK - England

Town: Littlehampton, W Sx

Length: no boat

MMSI: 235101591

Join Date: Jan 2012

Posts: 732

|

Quote:

Originally Posted by Anchorhandler

(P.S. Thanks for taking the time to do this Hugh).

|

They were a "finger in the air", "not to scale", "the value of your investment can go down as well as up" type bodge I hasten to add!

__________________

|

|

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

Recent Discussions

Recent Discussions |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|