|

|

27 June 2017, 22:20

27 June 2017, 22:20

|

#21

|

|

Member

Country: Ireland

Town: Galway

Boat name: Lucky

Make: Zodiac

Length: 6m +

Engine: Outboard

Join Date: Jun 2016

Posts: 69

|

Last post for tonight with pic

__________________

|

|

|

28 June 2017, 07:57

28 June 2017, 07:57

|

#22

|

|

Member

Country: UK - England

Town: Retford

Boat name: Spy-sea-one

Make: Excel 435

Length: 4m +

Engine: Suzuki Outboard/25/4

Join Date: Oct 2011

Posts: 7,534

|

very neat job indeed

__________________

|

|

|

28 June 2017, 11:07

28 June 2017, 11:07

|

#23

|

|

Member

Country: Ireland

Town: Galway

Boat name: Lucky

Make: Zodiac

Length: 6m +

Engine: Outboard

Join Date: Jun 2016

Posts: 69

|

Thank you @ jeffstevens763@g

I am very happy with the end results. Just some tidy up and cleaning and fitting the new valves left to do before she goes to the water

__________________

|

|

|

17 December 2017, 21:27

17 December 2017, 21:27

|

#24

|

|

Member

Country: Greece

Town: Thessaloniki

Boat name: Zodiac Futura S

Make: France

Length: 4m +

Engine: Mercury 30 HP

Join Date: Oct 2017

Posts: 21

|

Hello Simzpilot !

I'm glad I discovered someone who did such a job so well and presented it so clearly! Congratulations first and thanks for the effort to show us ! I have exactly the same type Zodiac Futura S 2001 model to refurbish and I'm trying to get information up until spring, posting in various threads ... English I know less and I did not understand if you unglued the whole floor or just the portion next to the transom. I also heard about the HH 66 and gathered only excellent opinions about it . . Why did not you try to stick PVC to PVC with the same HH66? It was especially noted for bonding this type (PVC to PVC) . Thank you

__________________

|

|

|

18 December 2017, 14:42

18 December 2017, 14:42

|

#25

|

|

Member

Country: USA

Town: S. Carolina

Boat name: D560

Make: Avon

Length: 5m +

Engine: 2016 Merc 115hp CT

Join Date: Aug 2013

Posts: 1,277

|

Copper/brass are not compatible with polyurethane or polychloroprene type adhesives.

For example, from the Bostik 2402 spec sheet:

"Bostik 2402 Adhesive should not be used in contact with brass, copper alloys, solutions or materials (e.g. some fabrics) that contain copper compounds which may migrate into the adhesive."

There is a negative chemical reaction that occurs.

At some point, is is likely that the repair will start to fail at the copper strip, migrating outward depending on the rate of copper oxidization.

Quote:

Originally Posted by maccardiolog

Hello Simzpilot !

I'm glad I discovered someone who did such a job so well and presented it so clearly! Congratulations first and thanks for the effort to show us ! I have exactly the same type Zodiac Futura S 2001 model to refurbish and I'm trying to get information up until spring, posting in various threads ... English I know less and I did not understand if you unglued the whole floor or just the portion next to the transom. I also heard about the HH 66 and gathered only excellent opinions about it . . Why did not you try to stick PVC to PVC with the same HH66? It was especially noted for bonding this type (PVC to PVC) . Thank you

|

HH66 is a non-crosslinked polyurethane type adhesive. It is similar to applying a two-part adhesive with no "Part B" mixed, or using the one-part repair tube glue. The longevity, strength, and hydrolysis resistance will be significantly inferior to a crosslinked two-part polyurethane adhesive.

__________________

Richard

Gluing geek since 2007

Opinions and intepretations expressed are solely my own and do not express the views or opinions of my employer

|

|

|

18 December 2017, 19:04

18 December 2017, 19:04

|

#26

|

|

Member

Country: Greece

Town: Thessaloniki

Boat name: Zodiac Futura S

Make: France

Length: 4m +

Engine: Mercury 30 HP

Join Date: Oct 2017

Posts: 21

|

With such chemical arguments no one can contradict you! Thanks again for advice !

Is there any difference between the products suggested by you: Bostik Vinycol 1520 and Bostik 2402?

You have previously said that it would be good to prepare PVC three times with MEK before applying glue. How should this be done practically ? Three times including cleaning old glue with MEK , if I do not have methilen chloride ? When should you apply the other two and at what intervals ?

I would have a question for simzpilot . I did not understand the part with the new 8 inch wide PVC strip and the copper strap , srews ....all that transom edges reinforcement ...maybe more pictures ...

__________________

|

|

|

18 December 2017, 21:53

18 December 2017, 21:53

|

#27

|

|

Member

Country: USA

Town: S. Carolina

Boat name: D560

Make: Avon

Length: 5m +

Engine: 2016 Merc 115hp CT

Join Date: Aug 2013

Posts: 1,277

|

Quote:

Originally Posted by maccardiolog

With such chemical arguments no one can contradict you! Thanks again for advice !

Is there any difference between the products suggested by you: Bostik Vinycol 1520 and Bostik 2402?

You have previously said that it would be good to prepare PVC three times with MEK before applying glue. How should this be done practically ? Three times including cleaning old glue with MEK , if I do not have methilen chloride ? When should you apply the other two and at what intervals ?

I would have a question for simzpilot . I did not understand the part with the new 8 inch wide PVC strip and the copper strap , srews ....all that transom edges reinforcement ...maybe more pictures ...

|

Bostik 2402 is for elastomers only (CSM/CR, "Hypalon").

You would need the Vinycol 1520. It is for plastomers (PVC / PU).

Scrub with MEK to remove old adhesive. Use a terry cloth. Sometimes a scotchbrite pad helps. Do not include this "scrubbing" time in your pre-wipe time for gluing.

///

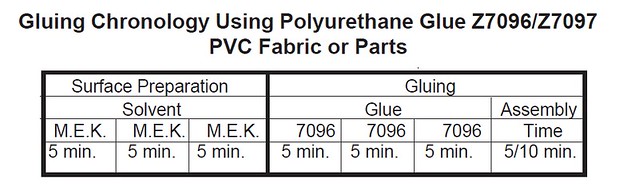

For gluing, follow this:

__________________

Richard

Gluing geek since 2007

Opinions and intepretations expressed are solely my own and do not express the views or opinions of my employer

|

|

|

21 December 2017, 15:19

21 December 2017, 15:19

|

#29

|

|

Member

Country: Greece

Town: Thessaloniki

Boat name: Zodiac Futura S

Make: France

Length: 4m +

Engine: Mercury 30 HP

Join Date: Oct 2017

Posts: 21

|

Thank you Kelson !

I picked up a lot of information on the net, but I would like to find out more from those who have actually renovated ...

Today I started detaching the pieces around the transom and found a complicated joint that I would like to replace, it's that white strap (photo ). I saw that simzpilot made a good adaptation, but is no longer present on the forum. Other looks and possibly pictures?

Also, on the entire length of the transom with pontoons, there is a smooth whitish glue film. How much should be cleaned with MEK , until the red color of the fabric appears?

I tried with a little acetone, sample, but no result. Perhaps I had to insist more. Thank you.

__________________

|

|

|

21 December 2017, 23:02

21 December 2017, 23:02

|

#30

|

|

Member

Country: USA

Town: San Diego

Make: zodiac futura mk2

Length: 4m +

Engine: Nissan 40 plus

Join Date: Oct 2008

Posts: 269

|

The photos are of where the transom meets the tube right? I'm not sure of exactly what your asking, but I just glued it regularly. It is necessary to do it in stages. You shouldn't glue a layer and then another right over it. You need to let the first layer outgas and cure first. Took a couple of days for me to reglue my transom.

The PVC two part glue does not bond well to old glue. MEK works a little better than acetone because it doesn't evaporate so fast. Some old glue will come off with a scotch brite pad. But I had a hard time getting my material totally clean. I also had some old badly made repairs that were almost impossible to get clean. Way too much glue! I used Dremel Finishing abrasive buffs to remove stubborn glue. With care you can remove the old glue without damaging the PVC fabric. It will take off a very small amount of surface, makes the PVC look dull. But the layer is going to be glued and bonded so I haven't hand any issues due to this. But be careful! Some small spots of old glue might not be an issue, but leaving old glue does weaken the bond.

__________________

|

|

|

21 December 2017, 23:23

21 December 2017, 23:23

|

#31

|

|

Member

Country: USA

Town: San Diego

Make: zodiac futura mk2

Length: 4m +

Engine: Nissan 40 plus

Join Date: Oct 2008

Posts: 269

|

One comment I would like to make, as you are gluing it is of course a one shot deal. So moving the boat around so that you have your work area positioned so you can properly make the layers go down is important. I flipped and flopped the boat to make bonding straight forward.

The second photo is of the front of the speed tube pocket. It had been poorly repaired. I HAD to use the abrasive wheel to get this right. You can see how there has been just a little surface layer removed. The cleaned areas look dull. Bonded beautifully.

Prep is everything

__________________

|

|

|

22 December 2017, 16:53

22 December 2017, 16:53

|

#32

|

|

Member

Country: Greece

Town: Thessaloniki

Boat name: Zodiac Futura S

Make: France

Length: 4m +

Engine: Mercury 30 HP

Join Date: Oct 2017

Posts: 21

|

Kelson, I'm glad you're helping me with a project I'm going to do soon.

1. Did you use the same grip of the transom on the pontoons as the original or you found another solution ?

2. In some areas where the old glue is not so obvious it's hard to see if you cleaned up well with MEK . How can you know that the area has been thoroughly cleaned if it is difficult to see the color change by removing the glue?

Excuse me for the many questions, but repair is a matter of everything or nothing, and if someone helps you not to do something wrong is desirable...

__________________

|

|

|

22 December 2017, 21:13

22 December 2017, 21:13

|

#33

|

|

Member

Country: USA

Town: S. Carolina

Boat name: D560

Make: Avon

Length: 5m +

Engine: 2016 Merc 115hp CT

Join Date: Aug 2013

Posts: 1,277

|

Order of operations:

1.) Remove transom, prep/clean everything.

2.) Sand and prime wood.

3.) Glue white "L" strip to transom wood.

4.) Glue white wedges to tube.

5.) Glue transom w/ L-strip to tube

6.) Glue trapezoidal PVC extrusion pieces tight against transom.

7.) Glue banana shaped PVC material finishing strips

8.) Glue top cover.

9.) Glue top cosmetic patch.

10.) Glue the back of the floor (stern, engine side)

11.) Glue the interior floor doubler

12.) Glue crystal tape over bottom transom corners.

13.) Glue pac-man / pie-cut pvc patches on bottom transom corners.

__________________

Richard

Gluing geek since 2007

Opinions and intepretations expressed are solely my own and do not express the views or opinions of my employer

|

|

|

27 December 2017, 20:06

27 December 2017, 20:06

|

#34

|

|

Member

Country: Greece

Town: Thessaloniki

Boat name: Zodiac Futura S

Make: France

Length: 4m +

Engine: Mercury 30 HP

Join Date: Oct 2017

Posts: 21

|

To simplify work and make sure the surfaces are clean (at least not be worried about one half...) , all pieces will be cut off from new PVC material. The workflows I have been given by Office888 are very clear, but :

1. ,,White strip,, from 3) is made of thinner fabric than the base material (strongan ) and its mounting seems too complicated (first photo ) . I would have chosen to mount a wider strip (strongan ?) over the semicircular edge of the transom, possibly with screws, then it will be glued together with transom on the pontoons . Do you have any link /photos with that solution ?

In some models, the transom was mounted in a plastic /rubber holder and it stuck to the pontoons-that seemed to me the best method, but ...

2 . Those ,, trapezoidal PVC extrusion pieces '' 6) are those in the second picture?

They seem to be rubber, not PVC. If it is rubber, stick with the same two-component PVC adhesive or need a primer ?

3. I have encountered unforeseen and undefined situations so far on this SIB model. That tape along the floor that comes between the two drain holes of the transom and which stick to the transom (last photo ) seems to be rubber and have traces of black seal on the surface when it was glued . Is it rubber? Is the same bicomponent PVC used? With or without primer?

__________________

|

|

|

27 December 2017, 21:25

27 December 2017, 21:25

|

#35

|

|

Member

Country: USA

Town: S. Carolina

Boat name: D560

Make: Avon

Length: 5m +

Engine: 2016 Merc 115hp CT

Join Date: Aug 2013

Posts: 1,277

|

Quote:

Originally Posted by maccardiolog

To simplify work and make sure the surfaces are clean (at least not be worried about one half...) , all pieces will be cut off from new PVC material. The workflows I have been given by Office888 are very clear, but :

1. ,,White strip,, from 3) is made of thinner fabric than the base material (strongan ) and its mounting seems too complicated (first photo ) . I would have chosen to mount a wider strip (strongan ?) over the semicircular edge of the transom, possibly with screws, then it will be glued together with transom on the pontoons . Do you have any link /photos with that solution ?

In some models, the transom was mounted in a plastic /rubber holder and it stuck to the pontoons-that seemed to me the best method, but ...

2 . Those ,, trapezoidal PVC extrusion pieces '' 6) are those in the second picture?

They seem to be rubber, not PVC. If it is rubber, stick with the same two-component PVC adhesive or need a primer ?

3. I have encountered unforeseen and undefined situations so far on this SIB model. That tape along the floor that comes between the two drain holes of the transom and which stick to the transom (last photo ) seems to be rubber and have traces of black seal on the surface when it was glued . Is it rubber? Is the same bicomponent PVC used? With or without primer?

|

You're not done yet. Unglue the wedges and the black strips from the tube with a heatgun.

1.) It's contact adhesive, it sticks to itself. You don't need screws. If it isn't sticking to itself TIGHT, then your glue is too wet or too dry, and you've made a mistake already. Glue the white "L" strip to the wood transom first. It'll stretch in place and form a tight "L" against the wood.

2.) The black "rubber" strips. They are made of PVC. Bond with two-part polyurethane adhesive (PVC adhesive).

3.) Correct, utilize two-part PVC adhesive.

ALL WOOD SURFACES MUST BE SANDED AND PRIMED.

__________________

Richard

Gluing geek since 2007

Opinions and intepretations expressed are solely my own and do not express the views or opinions of my employer

|

|

|

30 December 2017, 15:32

30 December 2017, 15:32

|

#36

|

|

Member

Country: Greece

Town: Thessaloniki

Boat name: Zodiac Futura S

Make: France

Length: 4m +

Engine: Mercury 30 HP

Join Date: Oct 2017

Posts: 21

|

Happy New Year to all !

I look forward to the renovation of the boat for which I work and in the last days of the year ... There have been some problems that I did not suspect. Because of the heat used to tear and the traction exerted, the black band suffered creases and stretched a little, that it no longer fits with the signs given as help for repositioning on the pontoon. Anyway, I'm going to use new material using it as a template, but I do not think I can stick it as original. I think it will make cute . I thought of making a few V-shaped cuts will avoid that (as in photo ) . Is it a good idea or should I use it uncut ?

Also, although I used the heat, the thicker black bands were greatly glued , so something material was lost ... I hope they do not influence the final result. Even though it has been since 2001, the boat has been repaired once, so it explains the very difficult split in some areas.

__________________

|

|

|

25 March 2020, 19:46

25 March 2020, 19:46

|

#37

|

|

Member

Country: Netherlands

Length: 4m +

Join Date: Jun 2017

Posts: 18

|

Quote:

Originally Posted by simzpilot

So this evening I decided to tackle some of the last major jobs left on the refurb. The main one being the transom reinforcement. .

|

May I ask for the effect you notice?

Is it a reinforcement against the push or pull force of the transom?

If it pulls the floor up, I could use two steel cables too?

__________________

|

|

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

Recent Discussions

Recent Discussions |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|